色选设备单色色选板故障的查找

来源:环球粮机网发布时间:2015-05-12 15:23:31

When there is a fault condition on the machine an animated exclamation mark icon will

be displayed in the bottom of the GUI screen on the right hand side.

当机器有故障时,在GUI屏幕下面的右手边将会显示一个跳动的惊叹图标。

Pressing this animated icon will bring up the ‘Fault information’ screen which will list the

fault or faults by type ie: ‘Calibration Fault’, pressing the + sign next to the fault type

will display the specifics of the fault ie: ‘Camera not calibrated Rear Visible 3’.

按这个惊叹图标,屏幕上出现“故障信息” (“Fault information”),它会列出故障或故障类型,

如:”Calibration Fault”(校准故障),按故障类型旁的“+”,将会显示故障的细节,

如:“Camera not calibrated Rear Visible 3”。

Fault conditions illuminate the fault lamp, turn the feed off and stop the machine from

sorting but do not inhibit any of the test or other functions available via the control

panel. Timed operations, e.g. Calibration, are also disabled.

故障情况将会使故障灯亮起,关掉喂料,并停止色选,但不会阻止通过控制屏提供的任何测试或其它功

能。定时的运行,如:校准,也会失效。

When changing components such as PCBs always follow the warnings and cautions

given on page ix in the Preface to the manual.

当更换元件如:印刷电路板,遵守手册前言中第ix页上的警告和小心的内容。

Certain faults, particularly power supply faults, may cause the machine to behave

erratically and will possibly generate misleading fault messages. For this reason, power

supply voltages should be routinely checked when trouble shooting.

If an unknown fault message is displayed, contact your Sortex representative.

某些故障,特别是电源引起的故障,可能会引起机器运行不定,并可能产生误导的故障信息。正因为此,

在进行故障查找时,应例行检查电源的电压。

如果显示了一条未知的故障,请与Sortex公司代表联系。

AIR PRESSURE FAULT

气压故障

If there is insufficient air pressure the machine will display an ‘Air Pressure fault’

如果气压不足,机器会显示“气压故障”(Air Pressure fault)

In the case of this fault the software inhibits all of the ejectors. Adjust pressure if

necessary using the regulator.

在这种故障的情况下,机器会关闭所有的喷嘴。如果有必要,用调节器调节压力。

Diagnosis/Response

诊断/原因

Air shut-off valve is turned off.

空气关闭阀关闭

Pressure regulating valve is set to incorrect pressure.

压力调节阀设定的压力不正确

No air supply or low pressure of air supply.

没有气源或低压气源

Air filter is clogged. Service the filter as described in Section 5.4.2. Ensure that the air

supply meets the stated requirements.

空气过滤器堵塞。过滤器的维修见第5.4.2。确保气源符合规定的要求。

Note The noise of the escaping air will attract attention should the pipe become

disconnected between the air pressure regulating valve and the ejector manifold.

注意:如果空气压力调节阀与喷嘴集合管间的管道断开了,那外泄空气的噪音会 引起注意。

Internal communications fault

内在的通讯故障

Ethernet以太网

(Ethernet communications are System controller to Media Converter box (UTP), then

Media converter box

to each sorting board).

(以太通讯包括从系统控制器到介质转换器盒(UTP),然后从介质转换器盒到每个色选板)。

1. Check media converter box power light is on, This is found to the left hand side of the

control cabinet.

2. Check BNC cable chain is terminated at both ends

3. Is Software Active LED (D30) on each Sorting Board Flashing

(if not board has crashed .. system reset)

1.检查介质转换器盒电源灯亮了,可以观察控制柜左手边。

2.检查BNC电缆链终止于两端。

3.在每个色选板上的LED是否闪光

(如果不闪光,表示板裂开了,系统重新设定)

Rs485

Check that the status lights on SIB, Vibrator board, each Lamp board, heated chute

board are not red ie. Board crashed.

检查SIB上的状态灯,振动器板,灯板,受热料槽板不发红,例如:板裂开了。

Check +5v_sys ok led on each board, ie receives power.

检查每个板上的+5V电压指示发光二极管, 意味着有电。

Check fuse (+12v) on pc interface board is not blown.

检查计算机界面板上的保险丝是否烧断。

Check final lighting board has terminator connection fitted.

检查最后的照明板安装了终止器连接。

Disconnect lamp boards by pulling apart in line connector front on power section to

electronics section divider

in control box.

通过拉开控制盒中电力部分前面的连接器到电子部分分配器,断开灯板。

Restart and see if problem goes away. (ie isolate lighting boards )

重新启动并看看问题是否解决了(即分开照明板)。

do same with cable going out of electronics box into power box.

同样把电缆从电子盒出来进入到电源盒中。

Camera boards 24V supply fault

照相机板24V供应故障

On a single camera this suggests a local wiring fault or possibly a camera fault.

On all cameras at once it suggests a System 24V under voltage. Power supply

or possibly wiring problem.

如果是一个单独的照相机,意味着现场的线路故障或可能是照相机故障。

如果是所有的照相机同时出现故障,意味着系统24V以下电压。电源供应或可能线路的问题。

No EOS signal

没有EOS信号

SIB may not be generating EOS.Possble SIB fault. Possible wiring fault on system bus.

Possible fault on individual sorting board.

If the fault is wiring local to SIB the "Synthetic EOS" light will be lit on all 3 sorting

boards. If it is only lit on a single Sorting Board then the fault is local to that board.

SIB可能不能产生EOS。可能是SIB故障。可能是系统总线上的电线故障。

可能单独色选板出现故障。

如果故障是局限在SIB上的配线造成的,“Synthetic EOS”灯将在所有3个色选板上亮起。如果只在一个

色选板上出现,那么故障就局限在那个板上。

F7

D97

D68

D67

F8

LP2

D20

F9

D17

D18

D19

F4

F3

360V REGD

360V

D29

D26

D27

D64

D21

D31

D66

D32

F2

LP1

D46

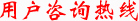

Lamp Driver Board - Fault Finding 灯驱动板-故障查找

The lamp drive board together with its 3 daughter boards (not shown here for clarity)

provides the following functions:

灯驱动板连同它的3块子板(这里未标明)提供如下的功能:

1. Drives up to 5 fluorescent tubes 1.驱动5个荧光管

2. Operates wiper & wiper safety cct. 2.操作清理刷和清理器安全cct

3. Operates filter. 3.操作过滤器

4. Operates background plate positioning system. 4.操作背景板定位系统

5. Supplies fans in optical box & on lamp board. 5.提供光电盒中和灯板上的风扇

6. Communicates with the system controller. 6.与系统控制器的通讯

Associated with these systems are various fuses and indicators which are related to

the functions and should be checked when a fault occurs:

与这些系统相连的有各种保险丝和指示器,它们与这些功能有联系,出现故障时必须进行检查。

Note: Access to the fuses and indicators will require the cover over the lamp board to

be removed exposing hazardous voltages. All normal warnings & precautions must be

observed.

注意: 在检修保险丝和指示器时必须罩住灯板防止高压伤人。必须遵守所有的警告和防范措施。

Affecting all systems 对所有系统影响

Fuse F7 – 500mA Nanofuse. This fuse protects the machine’s 24-volt supply from lamp

board faults. If this fuse blows no low voltage supply will be present on the lamp board

If LED indicator D31 (24V) is not lit check this fuse. Note that failure of the 24V supply

will prevent operation of all the lamp board functions.

If LED indicator D46 (FAULT) is on it indicates a processor software fault.

保险丝F7-500mA Nanofuse。此保险丝防止机器的24V供电引起的灯板故障。如果此保险丝烧断,那么灯板上就不会有低压供应。

如果LED指示器D31(24V)不亮,检查此保险丝。注意24V供电失败将会阻止所有灯板功能的运作。

如果LED指示器D46(FAULT故障)开着,意味着处理器软件故障。

If there is a general failure of lamp board functions check LED D21 (+5V). If this is not lit

no regulated 5-volt supply is present.

如果出现灯板功能全面的故障,检查LED D21(+5V)。如果灯不亮,那么就没有校准过的5V供电。

Affecting Fluorescent Lamp Drive 对荧光灯驱动影响

Fuse F2 6.3A. HRC – Live side mains supply

Fuse F3 6.3A. HRC – Neutral side mains supply

If neon indicator LP1 is not lit when mains supply is on, check fuses F2 & F3.

If neon indicator LP2 is not lit when LP1 has been on for 5 seconds board fault is

indicated.

If neon indicator ‘360V’ is not lit after LP2 is lit board fault is indicated.

Fuse F8 3.15A. HRC – High voltage lamp supply.

If neon indicator ‘360REGD’ is not lit after ‘360V’ is lit check fuse F8

保险丝F2 6.3A. HRC-Live side mians supply

保险丝F3 6.3A. HRC-Neutral side mians supply

如果主电源接通时毫微指示器LP1不亮,检查保险丝F2和F3.

如果LP2已经开了5秒钟但毫微指示器LP2不亮,表示出现板故障

如果LP2亮后毫微指示器’360V’不亮,表示出现板故障

保险丝F8 3.15A. HRC-高电压灯供应

如果’360V’亮后毫微指示器’360REGD’不亮,检查保险丝F8

If LED indicator D68 (15V_HVDC) is not lit lamp driver low voltage supplies have failed.

If LED indicator D67 (5V_HVDC) is not lit lamp driver 5-volt supply has failed.

If LED indicator D97 (5V_PLL) is not lit the phase lock loop synchronising the lamp drive

to the camera scan is not powered.

如果LED指示器D68(15V-HVDC)不亮,那么灯驱动器低电压供电失败

如果LED指示器D67(5V-HVDC)不亮,那么灯驱动器5V供电失败

如果LED指示器D97(5V-PL)不亮,那么灯驱动到相机流览同步的状态封闭回路

没电.

Affecting Wiper & Filter drive 对清理器和过滤器驱动影响

Fuse F4 1.5A. – Nanofuse. Protects supply to solenoid drivers. If D31 is on (so +24V is

reaching board) but D30 ‘+24V_SOL’ is off check this fuse.

保险丝F4 1.5A.-毫微保险丝。保护对电磁阀供电。如果D31开(这样24V到达板上)但是D30‘+24V-SOL’关,检查此保险丝。

If LED indicator D29 (WIPER) does not illuminate when a wipe is requested the drive on

the board is not operated.

LED indicator D32 (WIPER_1) illuminates when the wiper is at the end of stroke.

LED indicator D66 (WIPER_2) illuminates when the wiper is at the end of stroke and the

reed switch is actuated. Note that an LED in the switch is also operated in this state.

LED indicator D27 (FILTER) is illuminated when the filter is switched to position 1. This is a momentary action.

LED indicator D26 (SHUTTER) is illuminated when the filter is switched to position 2. This

is a momentary action.

如果要求清理操作时LED指示器D29(清理刷)没有照亮,那板上的驱动未工作。

当清理器处于行程的末端且簧片开关激活时,LED指示器D32(清理刷-1)照亮。

注意开关上的LED在此状态下也操作。

当清理器处于行程的末端且簧片开关激活时,LED指示器D66(清理刷-2)照亮。

注意开关上的LED在此状态下也操作。

当过滤器转换到位置1时,LED指示器D27(过滤器)照亮。这是一个瞬间作用。

当过滤器转换到位置2时,LED指示器D26(百页窗)照亮。这是一个瞬间作用。

Affecting Background Plate Positioning System

对背景板定位系统的影响

Led indicator D19 on - shows the background plate is fully open.

Led indicator D17 on - shows the background plate is fully shut.

Led indicator D18 on – changes state as the plate passes through the reference

position. Note that these LED’s can be observed to change state on power up of the

machine as the background plate is moved to initialise its position.

LED指示器D19开-表示背景板完全打开

LED指示器D17开-表示背景板完全封闭

LED指示器D18开-改变状态因为板经过了参考位置。注意可以在接通机器电源时观察这些LED改变状态,因为背景板被移动预置它的位置。

LED indicator D64 (FAULT) illuminates when the background plate has operated an

over-travel micro-switch. In this case no further operation of the background plate will

occur and the machine must be switched off.

To recover, if recovery is possible, and that will only be the case if a software fault has

caused the over-travel rather than a hardware fault, the red ‘over-ride’ button must be

held operated whilst the machine initialises on power-up. If recovery is possible the

background plate position will be re-initialised on power-up and the red button may

then be released.

If the background plate does not re-position on power up, shut down the machine and

replace the lamp board or position vane switches as required.

当背景板操作了重调微开关时LED指示器D64(故障)照亮。在此情况下,将不出现进一步的背景板操作,并且机器必须关机。

如果恢复有可能,而且这种情况只在软件故障引起重调而不是一个硬件故障,机器接通电源进行初始化时,

必须握住红色的’over-ride’按钮。如果恢复有可能的话,背景板将在接通电源时重新进行初始化然后可

以松开红色按钮。

如果背景板不能重新定位,那么关掉机器,按要求更换灯板或定位叶片开关。

Affecting 3 fans 对3个风扇的影响

2 for optical box cooling & 1 on lamp pack

Fuse F9 - 5A. HRC. If fans stop & D31 is on check this fuse.

2个用于光学盒的冷却,1个用于灯组

保险丝F9-5A,HRC。 如果风扇停止,D31开状态,那么检查此保险丝。

Affecting Communications with System Controller

对与系统控制器通讯的影响

LED indicator D20 on – shows 5 volts derived from 12 volts on system bus is present.

No communications if D20 not lit.

LED指示器D20 开状态-表示来自系统总线12V的5V电压供电。如果D20不亮,就没有通讯。

Z series Vibrator Board – Fault Finding

Z系列振动器板-故障查找

Note: Access to the fuses and indicators may in some cases require the cover over the

vibrator board to be removed exposing hazardous voltages. All normal warnings &

precautions must be observed.

注意:在某些场合检修保险丝和指示器时需要罩住振动器板防止高压伤人。必须遵守所有的警告和防范措施。

D4

D11

D3

F5

LP1

D9

D10

D8

D5

LP2

F4

LP3

F3

D7

F1

D4

Affecting Vibrator control system

振动器的控制系统

Fuse F1 375mA. Nanofuse protects 24V. supply to low voltage on-board 5V. supply.

保险丝F1 375mA.能提供24V电压给线路板上5V低电压供电。

LED indicator D6 is illuminated if 24V. supply is present.

如果24V供电,发光二极管指示器D6亮

LED indicator D5 is illuminated if 5V. supply is present.

如果5V供电,发光二极管指示器D5亮

LED indicator D4 is illuminated if a software fault occurs.

如果软件出现故障,发光二极管指示器D4亮

LED indicator D7 is illuminated if +5V. supply for feedback circuit is present.

如果反馈电路+5V供电,发光二极管指示器D7亮

LED indicator D8 is illuminated if -5V. supply for feedback circuit is present.

如果反馈电路-5V供电,发光二极管指示器D8 亮

LED indicator D10 is illuminated if +15V. supply referred to HVDC- and derived from DC to DC module M1 is present.

LED indicator D9 is illuminated if +5V

如果HVDC模块的+15V的输出到直流转换器M1的+5V供电,发光二极管指示器D9亮

Fuse F4 6.3A. HRC is mains supply live line fuse.

保险丝F4 6.3A. 是主电源相线保险丝

Fuse F3 6.3A. HRC is mains supply neutral line fuse.

保险丝F3 6.3A. 是主电源零线保险丝

Neon indicator LP2 illuminates to indicate mains supply to vibrator board present.

氖灯指示器LP2亮,表示主电源对振动板供电

Neon indicator LP3 illuminates to indicate mains supply to module PS1 has been switched on under software control.

氖灯指示器LP3亮,表示主电源到模块PS1开关已经在软件控制下接通

Fuse F5 3.15A. HRC protects the module PS1 from overload of it’s 360V output.

保险丝F5 3.15A.保护PS1避免360V输出过载

Neon indicator LP1 illuminates to indicate the 360V supply to the vibrator output drivers is present.

氖灯指示器LP1亮,表示对振动器驱动提供360V电压

Affecting Communication with System Controller

通讯控制系统

LED indicator D11 illuminates to indicate presence of +5V system bus voltage derived

from +12V system bus supply.

发光二极管指示器D11亮,表示来自系统电源的+12V +5V电压供电

D2

D2

D_12V

D_12SB

F1

Z series PC Interface Board – Fault Finding

Z系列PC接口板-故障查找

Affecting system bus communications

系统通讯

Fuse F1 1.5A. Nanofuse protects the system bus 12 volt supply lines.

LED indicator D_12SB illuminates to indicate presence of +12V to system bus.

保险丝F1 1.5A保护系统12V供电线路

发光二极管指示器D-12SB亮,表示+12V对系统供电

Affecting battery back-up, PC power, GUI communications

备份程序的电池,PC电源,操作屏通讯

LED indicator D_12V illuminates to indicate presence of +12V from connector P1.

发光二极管指示器D-12V亮,表示+12V对连接器P1的供电

LED indicator D1 illuminates to indicate presence of +5V from connector P1.

发光二极管指示器D1亮,表示+5V对连接器P1供电

Affecting GUI communications

GUI通讯

LED indicator D2 illuminates to indicate presence of +3.3V for LVDS drive to GUI.

发光二极管指示器D2亮,表示驱动操作屏的+3.3V供电

System Interface PCB Fault finding (LED status)

系统界面线路板故障查找(发光二极管状态)

D2

D33

D35

D32

D28

D29

D36

D30

D3

D37

D8

D9

D31

D34

D14

D4

D5

D15

D20

D1

D6

D11

D7

D10

D1 Illuminates Green to indicate the 24v dc supply to SIB is present.

D1 绿色表示对SIB的24VDC供电

D2 Illuminates Green to indicate the 24v dc external connection supply to SIB is present.

D2 绿色表示对SIB的24V外界连接供电

D3 Illuminates Green to indicate the PLD is programmed ok.

D3 绿色表示PLD程序正常

D4 Red On Microcontroller in reset or not programmed. D4 红色 开 微控制器出于重新设定或没有设定

Off Microcontroller running and ok. 关 微控制器运转正常

Flashing Microcontroller running but has a fault. 闪烁 微控制器运转但有故障

D5 Illuminates Green to indicate the Microcontroller is being programmed.

D5 绿色表示微控制器正在程序化

D6 Illuminates Red to indicate Primary hopper low.

D6红色表示第一个料斗处于低位

D7 Illuminates Red to indicate Secondary hopper low.

D7红色表示第二个料斗处于低位

D8 Illuminates Red to indicate Tertiary hopper low.

D8红色表示第三个料斗处于低位

D9 Illuminates Red to indicate Spare hopper low.

D9红色表示备用料斗处于低位

D10 Illuminates Red to indicate Secondary hopper full.

D10 红色表示第二个料斗满了

D11 Illuminates Red to indicate Tertiary hopper full.

D11红色表示第三个料斗满了

D14 Illuminates Green to indicate 5v regulated from 12v system bus supply is

present.

D14绿色表示12V系统总线调节为5V供电

D15 Illuminates Green to indicate 5v regulated from 24v supply is on.

D15绿色表示24V调节为5V供电

D20 Illuminates Green to indicate 12v system bus supply is ok (above 8v).

D20绿色表示12V系统总线供电正常(高于8V)

D28 Illuminates Green to indicate Spare input 0 is active.

D28绿色表示备用的输入0处于激活状态

D29 Illuminates Green to indicate Spare input 1 is active.

D29绿色表示备用的输入1处于激活状态

D30 Illuminates Green to indicate Chute lubrication control is on.

D30绿色表示料槽润滑控制处于开状态

D31 Illuminates Green to indicate Spare output 1 is active.

D31绿色表示备用的输出1处于激活状态

D32 Illuminates Green to indicate Spare output 0 is active.

D32绿色表示备用的输出0处于激活状态

D33 Illuminates Green to indicate Major alarm output is active.

D33绿色表示主要的警报输出处于激活状态

D34 Illuminates Green to indicate Minor alarm output is active.

D34绿色表示次要的警报输出处于激活状态

D35 Illuminates Green to indicate the Interlock output is active.

D35绿色表示互锁输出处于激活状态

D36 Illuminates Green to indicate the Interlock input is active.

D36绿色表示互锁输入处于激活状态

D37 Illuminates Red to indicate the Air input to machine is low .

D37红色表示输入到机器的空气处于低状态

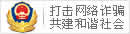

Mono Sorting Board Fault Finding (LED Status)

单色色选板故障的查找(LED状态)

D3, D30, D31, D19

D2

D16

D17

D13

D14, D25, D15, D18

D24

D8

D1, D26

D12

D1 Flashes green when there is data being transferred on the Ethernet

以太网上有数据传送时, D1闪绿色

D2 Illuminates green to indicate that the MACH devices have been programmed

D2显绿色表示MACH装置已经程序化了

D3 Illuminates green to indicate that the Xilinx devices have been programmed

D3显绿色表示Xilinx装置已经程序化了

D8 Illuminates green to indicate that +24V is present

D8显绿色表示24V供电

D12 Illuminates green when –9V Ethernet supply is present

D12显绿色,当-9V以太网供电

D13 Illuminates green when +5V supply is present

D13 显绿色,当+5V供电

D14 Illuminates red when the Ejector Drive Board is not present (ie: no signal from the

Ejector Drive Board)

D14显红色,当喷嘴驱动板无反应

(即:喷嘴驱动板不发出信号)

D15 Illuminates red to indicate that the sort is inactive on that board

D15显红色表示在那块板上的色选处于非激活状态

D16 Illuminates green to indicate that +2V5 supply is present

D16显绿色表示+2V5供电

D17 Illuminates green to indicate +3V3 supply is present

D17显绿色表示+3V3供电

D18 Illuminates red to indicate there is an air pressure fault on the Ejector Drive Board

D18显红色表示在喷嘴驱动板上有空气压力故障

D19 Illuminates red to indicate that there is no EOS signal being received from the systembus connection

D19显红色表示没有收到来自系统总线连接的EOS信号

D24 Illuminates green when +5V supply is present

D24显绿色,当+5V供电

D26 Illuminates red to indicate that there is an Ethernet collision occurring (this is

suggestive of Ethernet communication problems ie: terminator removed)

D26显红色表示以太网输送冲突发生(认为是以太网传输的问题,即终止器被移去了)

D30 Illuminates green to indicate that the software is active

D30显绿色表示软件激活

D31 Illuminates red to indicate that the system is undergoing a reset

D31显红色表示系统正在进行重新设定

OTHER FAULTS

This section lists some of the faults that may occur without resulting in a displayed fault

message, together with suggested causes and remedial action.

No Power: Power Indicator not lit

WARNING

ISOLATE THE MACHINE FROM THE ELECTRICAL SUPPLY BEFORE TOUCHING ANY ELEC

TRICAL COMPONENTS

Check that the mains supply is available to the sorter. If the power is supplied via a

separate site isolator, check that it is switched on.

Check for short circuit or overheating components before switching on again.

Feed Sstem Becomes Noisy

Check that the vibrator leaf springs are not broken. Replace vibrator assembly as

necessary.

Check that the top of the feed chutes or bottom of the hopper do not contact the feed

trays. Re-align if necessary.

Check that none of the fixings that secure the various components of the feed system

have worked loose.

Vibrator magnet poles may be striking together. Isolate the machine from the electrical

supply, dismantle and examine the vibrator.

Vibrator Lacks Power Even at Max. Feed Rate

Check that the vibrator leaf springs are not broken. Replace vibrator assembly as

necessary.

Machine Not Sorting, Product Feeding

Check that the required Sensitivities are enabled and set for an optimal sort. (If

necessary, recall mode).

Check that the required views are turned on.

Machine Continually Wipes

Check the feed rate. Excessive feed rates can prevent the machine from maintaining

calibration. Turn the feed rate down.

Excessive build up on viewing windows. Stop the machine, switch off the power and

clean the windows.

Excessive loose particles in viewing area. Check dust extraction working satisfactorily.

Excessive Amount of Reject in Accept

Check that the required sensitivities are enabled and set for an optimal sort. (If

necessary, recall mode).

Wrong mode selected.

Check air pressure setting.

Check ejectors.

Check ejector delay settings.

Check that feeding into centre of scanning area.

Excessive Amount of Good Product is Rejected

Check that only the required sensitivities are enabled and that they are set for an

optimal sort.

Wrong mode selected.

No Power to the System (Power ON lamp not illuminated)

Check that general mains isolator is ON.

Check site mains input is ON.

Check that power lamp has not failed.

Sorting Efficiency Progressively Deteriorates

Ensure that routine cleaning is being performed adequately.

Check that the feed chutes are not worn, damaged or misaligned. Replace or adjust as

necessary.

Run the ejector test. Replace any ejectors that fail to operate. If any faulty ejectors are

found, check to see if the air filter of the Air Set is clogged.

WARNING THE FILTERS FITTED TO THE AIR SET ARE NOT DESIGNED TO COPE WITH

BADLY CONTAMINATED AIR AND SERIOUS DAMAGE TO THE EJECTION SYSTEM WILL

RESULT IF MOISTURE OR OIL IS ALLOWED TO REACH THE EJECTORS

Test the wipers, if they fail to work, check to see if the fault is electrical; if not the fault

is pneumatic. If the wipers are functioning check that the wiper brushes are keeping

the viewing system windows clear of waste from the commodity and that they are not

worn. Replace brushes or adjust wiper arm as necessary.

Sort Inefficient

Perform a calibration.

Sensitivity setting too low.

Overfeeding: lower the feed rate.

Wrong sorting mode for product.

Microprocessor is affected by interference.

Air pressure too low (or possibly too high).

Dividing edge incorrectly positioned.

Incorrectly set up.

Very Heavy Rejection After Recalibration

The machine is set to the wrong mode for the product.

Incorrect filters are fitted.

The viewing windows are dirty.

Machine Continually Calibrates

Check that there is no excessive build up in the viewing area, stop the machine and

clean the windows if necessary.

Check that there are not excessive loose particles in the viewing area, ensure that the

dust extraction is working satisfactorily.

Check the camera signal levels (Engineering, Camera Facilities, Camera Signal)

公告信息:

公告信息: